Managing Director, Aerospace Division

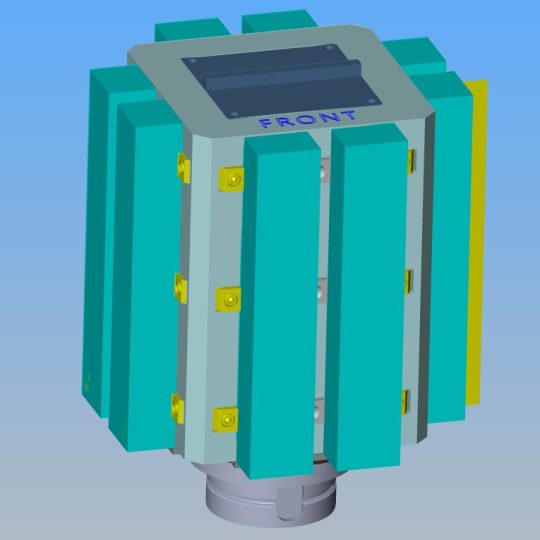

After APC explained the benefits of creating a proper tool database to us, we was more than happy to hand the task over to the experts. What they created for us was truly astounding and now every single cutter, tool holder and vice that was in the building was in the database. The clever part to this was that all the cutting data for each tool was in the database, we could select what material we’d be machining at the beginning of programming the job, then only tools specific for that material application would appear with all the speeds and feeds already pre-set as per the manufactures recommendations.

This has been an investment that started paying for itself from day one both in time and money. We save at least 2 hours on every single job as there is no cutting data entry or looking through endless tool catalogues, meaning we now have standardisation across our factory for every programmer which has enhanced tool life tremendously thus saving us a fortune in tooling costs!

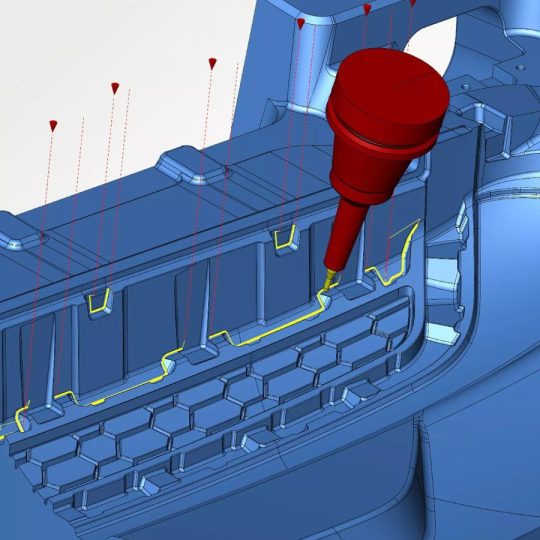

We also have all the work-holding in one easy to use file which is then copied across to each job for simulation purposes, this means we are now collision checking every single job before it runs on a machine.

If you don’t have a setup like this I highly recommend APC to enhance your factory!